The DC series motor attains dangerously high speed when we run it on no load. The main reason for overspeeding is that at no load, the flux produced by the field winding is much less.The reduced flux causes overspeeding of the motor.

The speed of the motor is inversely proportional to the flux.

To understand why this happens, let’s explore the construction, speed equation, and how back EMF influences the performance of a DC series motor.

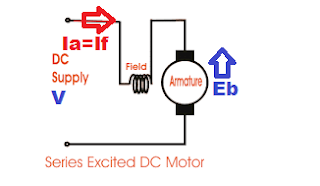

Series Winding in DC Series Motor

In the DC series motor, the field and armature windings are connected in series, and both windings carry the same amount of current. The field winding has to carry the full-rated armature current. it has fewer turns of thicker wire.

This winding arrangement directly influences how the motor’s speed behaves — let’s examine the speed equation to see how.

Speed Equation of DC Motor

The speed of the DC motor is proportional to the back EMF(Eb) and inversely proportional to the flux. The flux is proportional to the field current.

In the DC series motor, the field current and the armature current are the same. Therefore, the flux in the motor is proportional to the armature current(Ia).

N = K1 × Eb / Φ ———–(1)

Where:

N = Speed of the motor

Eb = Back EMF of the armature

Φ = Flux

K1 = Constant

Now that we understand how flux and speed are related, let’s look at the role of back EMF and how it forms inside a DC series motor.

How Back EMF is Generated in a DC Series Motor

When the armature current flows, the armature inductance opposes it. To impede the armature current, the voltage of the opposite polarity to the applied voltage(V) is induced in the armature. The voltage induced in the armature is known as the back EMF(Eb).

According to Kirchoff’s current law, the algebraic sum of all the voltage around any closed loop in a circuit is zero.

V + Ia(Ra + Rf) + Eb = 0 ———–(2)

Where,

Ra= The armature resistance

Rf= The field resistance

V= Applied Voltage

Solving for Eb:

Eb = V – Ia(Ra + Rf) ———–(3)

We also have:

Eb = N × Φ ———–(4)

Substituting equation (4) into (3):

K1 × N × Φ = V – Ia(Ra + Rf)

Now:

N = [V – Ia(Ra + Rf)] / (K1 × Φ)

As:

Φ ∝ Ia ⇒ Φ = K2 × Ia

So:

N = [V – Ia(Ra + Rf)] / (K1 × K2 × Ia)

Let:

K3 = V / (K1 × K2)

K4 = (Ra + Rf) / (K1 × K2)

Therefore:

N = K3 / Ia – K4 ———–(5)

This final equation gives us a clear insight into what happens when the motor runs with very little or no load.

Why Overspeed Occurs at No Load

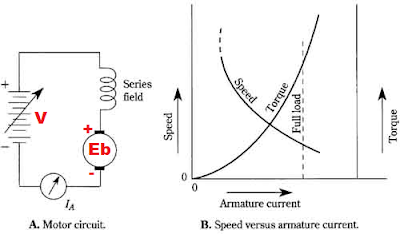

From equation (5), it is clear that the speed of the DC series motor is inversely proportional to the armature current.

The armature current v/s speed characteristics of the DC series motor are given below.

At no load, the armature current of the DC series motor is very low. If the motor is operated at no load, the motor will attain an enormously high speed that can physically damage the rocker arm assembly and the motor parts.

This is the same scenario seen when a separately excited DC motor is started without switching on the field supply.

Why Motor Should Be Started with Load

When the DC series motor is connected to the load at the start of the motor, the motor draws more armature current compared to the starting current with motor operation at no load, and the speed of the motor increases in a controlled way.

The DC series motor must not be tested on no load condition.

Conclusion: Never Start a DC Series Motor Without Load

For the above reasons, the DC series motor should not be started at no load. Doing so risks overspeed, mechanical failure, and serious equipment damage.

Frequently Asked Questions (FAQs)

A DC series motor should be started with load to ensure enough armature current flows through the windings. This generates sufficient flux and prevents the motor from reaching dangerously high speeds.

At no-load, the current is minimal, leading to weak flux. According to the speed-flux relation, this causes the motor to accelerate uncontrollably, which may damage its components.

If started without load, the DC series motor draws very little current. The reduced flux causes the motor to overspeed, which may lead to mechanical failure or safety hazards.

It is unsafe because the motor’s speed increases rapidly when flux is low. This overspeeding can result in excessive vibration, noise, and damage to the motor’s internal components.

No, it is not recommended. Always use a dummy mechanical load or brake during testing to mimic real operating conditions and prevent overspeeding.

Related Articles:

Interesting to learn with you

You are good principal.