Earthing, grounding, and neutral are often confused terms in electrical systems—but they serve different safety and functional purposes. While “grounding” and “earthing” are sometimes used interchangeably, they differ in meaning based on regional standards and application.

This guide will break down the difference between earthing, grounding, and neutral in simple terms with real-world examples.

Earthing: Connects the equipment body (non-current-carrying parts) to the earth for human safety.

Grounding: Connects the system neutral to the earth for handling fault current and system protection.

Neutral: Acts as a return path for current in normal operation.

What is Grounding in Electrical Systems?

The term grounding is commonly used in the electrical industry to mean both “equipment grounding” and “system grounding.” Both serve essential roles in ensuring electrical safety and stability.

What is System Grounding?

System grounding refers to the practice of connecting the neutral point of a power system (such as a transformer or generator) to the earth to ensure system stability and safety during fault conditions.

The neutral of the transformer must be earthed to the ground. Solid earthing is used for the equipment with a voltage rating of less than 600 volts.

The large rating transformer is earthed through the neutral grounding resistor (NGR) to limit the fault current to its full load current.

The value of the NGR is:

R = (Vph / √3) × If

Where,

Vph – Phase Voltage

If – Full load Current of equipment

A current transformer (CT) may be connected between the neutral and the earth point. The unbalanced current flowing through the CT can be fed to a protective relay for circuit protection.

When the live part of the equipment is connected to the earth, the potential setup is known as system grounding.

Under normal operation, the potential at the neutral point is zero, but it rises during a fault condition. The unbalanced phase currents get added and flow through the neutral. This results in a potential rise at the neutral point, causing current flow to the earthing or grounding point.

Grounding is typically applied to:

- Dyn11 vector group transformers used for distribution

- Current transformers (CTs) used for equipment protection

What is Equipment Grounding?

The process of connecting the frame or enclosure of electrical equipment to the ground point is called equipment grounding, which is synonymous with equipment earthing.

It ensures that any leakage current or fault current does not energize the equipment body.

In case of insulation failure, the grounding path allows the fault current to flow to the earth, which prevents electric shock and enables protective devices like circuit breakers or fuses to trip safely.

What is Neutral in Electrical Systems?

Neutral serves as a return path for electric current, thus completing the electrical circuit.

In a single-phase circuit, the phase current flows through the neutral to complete its path. As a result, the phase current and the neutral current are equal in this type of circuit.

In a three-phase, four-wire electrical system, the neutral current flows only when the loads connected to the three phases are not balanced. When the loads are balanced, no current flows through the neutral.

You may have noticed that the neutral point is absent in the stator of an induction motor, which is connected to three phases. This is because the motor acts as a balanced load, and there is no possibility of current flow through a neutral conductor.

The phase current becomes unbalanced during a fault condition, causing unbalanced current to flow through the neutral. The neutral point is grounded to divert fault current and protect the equipment from abnormal current.

Read detailed article on: Importance of Neutral Wire

What is Earthing in Electrical Systems?

Earthing refers to the process of connecting the non-current-carrying parts (like metal enclosures) of electrical equipment to the earth.

This ensures that in case of insulation failure, leakage or fault current safely flows to the ground instead of passing through a human body or damaging equipment.

The electrical devices are housed in a panel called enclosure. The panel is an isolated enclosure that provides necessary insulation between the live parts and the enclosure.

If the insulation fails or any conductor gets disconnected and touched by the enclosure body, the enclosure body will attain the live potential.

If a person touches the enclosure, he may get an electric shock. The enclosure is connected to the earth’s potential to protect the man and machine so that the current will be passed to the ground.

The following electrical equipment must be earthed from at least two different points on the body, each connected to separate earth pits:

- Electrical panels

- Electric motors

- Generators

- Transformers

- Any other high-voltage electrical equipment

This dual-point earthing ensures both personnel safety and equipment protection under fault conditions.

Read detiled article on: Why is double earthing necessary for 3-phase machines and equipment?

Importance and Safety Role of Earthing

Earthing plays a critical role in protecting both people and equipment in electrical systems.

Protects Human Life: If someone accidentally touches a live part, earthing provides a safe path for fault current to flow into the ground, reducing the risk of electric shock or electrocution.

Protects Equipment: During insulation failure or fault conditions, earthing helps divert leakage or fault current away from sensitive components. This prevents equipment damage, overheating, or fire.

Enables Safe Operation: It ensures the metal body of equipment stays at zero potential, making it safe to touch.

Triggers Protective Devices: Earthing causes a high fault current flow, which quickly trips fuses or circuit breakers, isolating the faulty circuit.

Differences Between Grounding, Neutral, and Earthing – Comparison Tables

To clearly understand the distinct roles of grounding, neutral, and earthing in electrical systems, the tables below break down their key differences

Grounding vs. Neutral – Comparison Table

The table below highlights the fundamental differences between the two to clarify their functions, current behavior, and system impact.

| Aspect | Grounding | Neutral |

| Purpose | Safety: Diverts fault current to earth | Carries return current in normal operation |

| Carries current during normal operation? | No | Yes |

| Type of current | Only during faults | Normal and unbalanced fault current |

| Connection point | Equipment body or neutral point to earth | Return line from load to power source |

| Voltage potential | Zero under normal conditions | Zero under balanced load, may rise in fault |

| Safety function | Prevents shock by providing a low-resistance path | Ensures circuit continuity |

Grounding vs. Earthing – Comparison Table

Though grounding and earthing are often used interchangeably, particularly across regions, there are subtle yet critical distinctions.

Grounding connects the system’s neutral point to the earth, whereas earthing connects equipment enclosures to protect against shock.

| Aspect | Grounding | Earthing |

| Definition | Connecting neutral point of system to ground | Connecting non-current-carrying parts of equipment to ground |

| Purpose | Diverts fault current to ground to protect system | Protects users from electric shock due to insulation failure |

| Current Flow | Carries fault current | Carries leakage or fault current |

| Connection | Neutral or star point of transformer/generator | Metal body or enclosure of electrical equipment |

| Color Code (India) | Black | Green |

| Potential | May vary depending on fault condition | Always at earth potential (zero volts) |

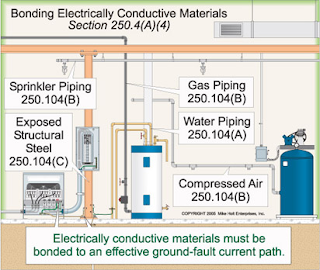

What is Bonding in Electrical Systems?

The metallic items that are not designed to carry electricity in the room or building are intentionally connected to the earth to avoid the possibility of electric shock. The process is known as bonding.

All the equipment connected will be at the same potential, and if someone touches two pieces of equipment simultaneously will not get an electric shock because no current flows if the potential difference is zero.

If the phase conductor touches the metal part, the equipment will get the electrical potential. This will cause a large current to flow through the bonded piece of equipment to the ground, and the circuit breaker will get tripped.

Conclusion

Earthing and grounding are critical for protecting equipment and people. The neutral connected to the earth point is system grounding, while connecting the equipment body to earth is equipment grounding or earthing.

Frequently Asked Questions(FAQs)

Earthing connects non-current-carrying parts to the earth to prevent shock. Grounding connects the neutral point to the earth to manage fault current safely.

No. Neutral acts as a return path for current in AC systems. Ground is used to discharge fault current and ensure safety.

In some regions like the U.S., “grounding” includes both system and equipment grounding. In other regions, “earthing” is used specifically for equipment enclosures.

Improper earthing can lead to electric shock, equipment damage, or even fire during faults.

Related Articles: