There are two types of 3-phase induction motors. These are the squirrel cage induction motor & slip ring induction motor. We shall discuss the application of squirrel cage induction motor & slip ring induction motor in this article. The working principle of the squirrel cage and slip ring induction motor is based on Faraday’s law of electromagnetic induction. The torque of the induction motor depends on the rotor resistance.

The end rings short-circuit the rotor of a squirrel cage induction motor, and therefore, it is impossible to connect external resistance to the rotor winding. At the same time, it is possible in slip ring induction motor.

The Squirrel cage induction motor is simple, rugged, and reliable. However, the motor can’t produce as much starting torque as the slip-ring motor can produce. The squirrel cage induction motor drives the loads that demand low starting torque.

The torque of the induction motor is,

T=slip*Es*Ir*cosΦ

cosΦ=Rr/√(Rr^2+s*Xr^2)

The power factor of the squirrel cage induction motor is very low at the start because the rotor is highly inductive. The power factor of the motor improves as the speeHowever, and the motor can’t produce as much starting torque as the slip ring …d of the motor increases.

The starting torque of the squirrel cage induction motor is low. Therefore, the motor is unsuitable for applications that demand higher starting torque. The use of a double cage rotor can improve the starting torque of the squirrel cage induction motor.

Applications of Slip ring Induction Motor

Large inertial loads like rolling mills, bucket elevators, and cranes demand higher starting torque, and for driving such loads, the slip-ring motor is a perfect choice. A slip-ring induction motor can produce 250–300 % starting torque.

The torque of the slip ring induction motor,

T=slip*Es*Ir*cosΦ

cosΦ=(Rr+R)/√(Rr+R)^2+s*Xr^2)

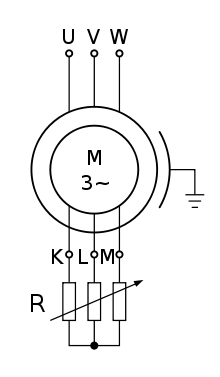

R- External resistance

The external resistance is added to the rotor conductor to improve the starting torque of the motor.

The external resistance improves the power factor, reduces the starting current, and, as a result, improves the starting torque. The maximum resistance is added to the rotor resistance to produce higher starting torque, and the resistance is decreased as the motor accelerates toward its base speed. At the base speed, the rotor conductor is short-circuited by the shorting contactor of the Liquid rotor starter( LRS )/ Grid Rotor Resistance(GRR).

The slip ring induction motor is suitable for the application where,

- The Applications that demand higher starting torque need a slip-ring induction motor. Therefore, a ring induction motor is suitable for driving high inertia loads.

- Speed control is required ( the speed can be controlled through a Grid resistance regulator. Also, there is substantial power saving if used for driving the centrifugal fans and pumps. The other option of power saving is the slip power recovery system. The rotor copper loss or the slip power is recovered and returned to the mains. Thus, with SPRS, the total recovery of the slip power is possible. The SPRS is more efficient than GRR.