Squirrel cage and slip ring induction motors are widely used in industrial and commercial applications due to their ruggedness and efficiency. While both are types of induction motors, their rotor designs make them suitable for different use cases.

Let’s explore the major applications of squirrel cage induction motor and applications of slip ring induction motor.

What is a Squirrel Cage Induction Motor?

The squirrel cage induction motor is the most commonly used AC motor due to its simple and robust construction. It is named after the squirrel cage-like structure of its rotor.

Applications of Squirrel Cage Induction Motor

The applications of squirrel cage induction motor are found in systems that require low starting torque and consistent speed.

- Fans and blowers

- Water pumps

- Air compressors

- Conveyor belts

- HVAC systems

- Lathe machines

- Drilling machines

These applications benefit from low starting torque and constant speed operation.

What is a Slip Ring Induction Motor?

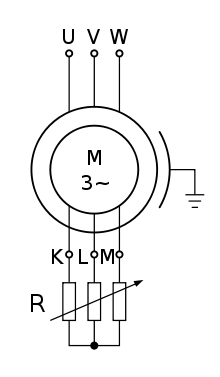

A slip ring induction motor has a wound rotor connected through slip rings to external resistances. This allows better control over starting torque and speed.

Applications of Slip Ring Induction Motor

The application of slip ring induction motor is ideal for heavy-duty machinery that demands high torque and adjustable speed control.

- Cranes

- Elevators

- Rolling mills

- Hoists

- Bucket elevators

- Centrifugal pumps

- Winches

A slip ring induction motor can produce 250–300% starting torque, making it ideal for driving high-inertia loads.

In addition to torque, speed control can be achieved using a Grid Resistance Regulator (GRR). For greater energy efficiency, especially in centrifugal fans and pumps, the Slip Power Recovery System (SPRS) can be employed.

SPRS allows the recovery of rotor copper losses (slip power) and feeds them back to the mains supply. This not only reduces energy waste but also makes SPRS more efficient than GRR in the long term.

Thus, slip ring motors are best suited for applications where:

- Frequent starts/stops occur

- Load conditions vary

- High torque and energy-saving options like SPRS are critical

Types of 3-Phase Induction Motors

The two main types of 3-phase induction motors are the squirrel cage motor and the slip ring motor, each suited for specific use cases.

Both work on the same basic principle but differ in rotor design and application suitability.

Working Principle of Squirrel Cage and Slip Ring Induction Motor

Both squirrel cage and slip ring induction motors operate on Faraday’s law of electromagnetic induction.

Read detailed artcile on: Faraday’s Laws of Electromagnetic Induction

Squirrel Cage vs Slip Ring Rotor Design

- The squirrel cage rotor is permanently short-circuited using end rings, making it impossible to connect external resistance.

- The slip ring rotor, however, provides access to the rotor windings through slip rings, allowing external resistance to be added during starting.

Features of Squirrel Cage Induction Motor

- Simple and rugged construction

- Low maintenance

- Not suitable for high starting torque applications

- Commonly used for constant load and low starting torque applications

Torque Equation of Induction Motor

The torque T developed in an induction motor can be expressed as:

T=slip×Es×Ir×cosϕ

Where:

- slip = rotor slip

- Es = rotor-induced EMF

- Ir = rotor current

- cos Φ = power factor of the rotor circuit

This torque equation highlights how torque depends directly on slip and power factor, which makes slip ring motors more suitable for high starting torque conditions, especially with external rotor resistance added.

Power Factor in Induction Motor

The power factor of an induction motor is defined by the equation:

cosΦ=Rr/√(Rr2+s* Xr2)

Where:

- Rr = rotor resistance

- Xr = rotor reactance

- s = slip

In squirrel cage induction motors, the rotor is highly inductive at startup, which results in a very low starting power factor. As the motor accelerates, the slip reduces, the reactance becomes less dominant, and the power factor improves.

However, due to fixed rotor resistance, squirrel cage motors still offer lower starting torque compared to slip ring motors.

Read detailed artcile on: Why does an Induction Motor has Poor Power Factor at NO Load?

Limitations and Improvements of Squirrel Cage Induction Motor

The starting torque of the squirrel cage induction motor is low. Therefore, the motor is unsuitable for applications that demand higher starting torque. The use of a double cage rotor can improve the starting torque of the squirrel cage induction motor.

Slip Ring Motor Torque with External Resistance

The torque of the slip ring induction motor,

T=slip*Es*Ir*cosΦ

cosΦ=(Rr+R)/√(Rr+R)2+s*Xr2)

Where, R- External resistance

The external resistance is added to the rotor conductor to improve the starting torque of the motor.

The external resistance improves the power factor, reduces the starting current, and, as a result, improves the starting torque.

The maximum resistance is added to the rotor resistance to produce higher starting torque, and the resistance is decreased as the motor accelerates toward its base speed.

At the base speed, the rotor conductor is short-circuited by the shorting contactor of the Liquid rotor starter( LRS )/ Grid Rotor Resistance(GRR).

Which Motor Type to Choose for Your Application?

- Choose slip ring induction motor where high starting torque and speed control are required, especially with large or variable loads.

- Choose squirrel cage induction motor for simple, low-starting torque applications where reliability and low maintenance are essential.

Conclusion: Choosing the Right Induction Motor

Squirrel cage and slip ring motors both have their advantages. Your choice depends on the application’s torque requirements, cost constraints, and control needs.

For high efficiency and low maintenance, squirrel cage motors are preferred. For heavy-duty start-up and speed control, slip ring motors are the best fit.

FAQs

It is widely used in fans, pumps, compressors, and HVAC systems requiring low starting torque.

Used in heavy load machines like cranes, rolling mills, and elevators that need high starting torque.

The main difference is in rotor construction and applications. Slip ring motors allow external resistance for torque control; squirrel cage motors do not.

Not typically, unless equipped with a double cage rotor. Slip ring motors are better suited for such applications.

Related Articles: