Direct online starter is a method of starting an induction motor. The stator of the motor receives the full supply voltage in the DOL starter. Therefore, a Direct Online Starter is suitable for starting the small rating three-phase induction motors. We will also discuss the DOL power circuit diagram. The DOL starter control circuit diagram is also very important for understanding the working of a DOL starter.

Types of Starters for an Induction Motor

Three types of starters are mainly used for starting a squirrel cage induction motor.

- DOL( Direct Online Starter)

- Star Delta Starter

- Soft Starter

- V/f Drive ( Used for soft starting and speed control)

Direct online or DOL Motor Starter

The Direct On Line starter is the simplest form of motor starter. The direct online starter is a basic and simple starter for starting the induction motor. In DOL Starter, we connect the stator winding of the induction motor directly to the three-phase supply voltage. Thus, the stator winding receives full line voltage.

The DOL motor starter is suitable for starting small-rating motors because the motor draws about 6 to 8 times its full-rated current at the starting time when the stator winding gets the full-rated voltage.

Why does the induction motor draw 6 times the starting current with the DOL starter?

The reasons for drawing a high starting current are as follows;

- The rotor is highly inductive because the rotor current frequency is equal to slip times the stator frequency. The slip of the rotor current is unity at the start. Thus, the rotor reactance is very high(XL =2πsfs). Therefore, the induction motor’s rotor draws a very high current at the start.

- At the start, the induced voltage across the stator winding is zero, and there is no opposing EMF against the applied voltage; thus, the stator’s winding resistance only limits the starting current.

In the absence of EMF at the time of starting, the motor draws about 6 to 8 times the current of its full load current.

Why is the induction motor power factor Poor with the DOL starter?

Moreover, the motor’s power factor is very low and draws a large magnetizing current. The motor takes about 6-8 times when it is started, and the current magnitude decreases as the motor accelerates towards its base speed(full rated speed). Even though the motor draws a large current at the start, it delivers very low starting torque. The DOL starting is suitable for small-rating induction motors.

If large rating induction motors are started with the DOL starting method, a heavy starting current can cause a voltage dip in the supply system and may damage the motor.

The large rating induction motor can be started on DOL if the capacity of the power network permits. If the large rating transformer is used for the distribution of three phases of 440 volts, the large rating motor up to 90 KW can be started on DOL. However, the DOL starting of 5.5 KW motor is feasible in domestic connections.

The Direct-on-Line Starter usually mainly consists of two parts:

- Control Part – Contactors and Push Buttons

- Protection Part – Overload Relay

Working Principle of DOL Starter

The full line voltage is applied to the stator for the starting of the phase induction motor. The DOL starter is suitable for a small-rating three-phase squirrel cage induction motor.

Direct Online Starter Circuit Diagram

The Direct online starter circuit diagram can be divided into two parts.

- Power Circuit Diagram

- Control Circuit Diagram

DOL Starter Power Circuit Diagram

The Power Circuit Diagram of the DOL starter consists of the following parts.

- MCCB or Switch Fuse Unit

- Motor Protection Circuit Breaker(MPCB) Or O/L Relay

- Power Contactor of AC3 rating

The motor protection circuit breaker protects the motor from short circuits and overloading conditions.

DOL Starter Control Circuit Diagram

The control circuit of the direct online Starter is given below. The control circuit has the following components.

1. Auxiliary contactor

2. Start Push button

3. Stop Push Button

4. Indication Lamps- ON/OFF/Over Load

Working of DOL Starter

When the start push button is pressed, the contactor C2(main Contactor of AC3 rating ) operates. If the overload relay is healthy and the stop push button is in the released state, then the full voltage is applied to the motor. The main contactor C2 remains in its on state by holding contact of the main contactor C2 after releasing the start push button. Thus, the supply to the stator is available after releasing the start button. We can stop the motor by pressing the stop switch. If the load on the motor exceeds its rated capacity, the overload relay signals and trips the contactor C2, and the motor trips.

The wiring diagram of the Direct online motor starter is given below.

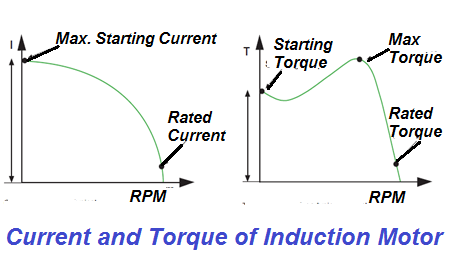

The motor draws a large current, and it starts reducing when the motor attains its base speed. The motor current and torque are given below.

When the stop push button is pressed, the main contactor C2 drops, and the motor stops.

In the case of jamming from the load side or problem in the motor like single phasing or unbalanced voltage, the motor draws a large current above its full load current(FLC), and the thermal overload relay will get tripped with an overloading fault. The contact of the overload relay QM1 drops the main contractor C2; thus, the motor stops due to overloading. The overload relay can be a thermal overload type or an electronic relay.

In electronic overload relays, apart from the overload protection, the negative sequence current fault(I2), earth fault protection(Io), and stall protection are also available, and the motor can be protected if these faults occur.

Advantages of DOL Starter

- Simple, most economical, easy to understand starter.

- It is more comfortable to design, operate, and control.

- It provides nearly full starting torque at starting.

- Easy to troubleshoot.

- DOL starter directly connects the supply to the delta winding of the motor, so there is no complexity in the circuit diagram

Disadvantages of DOL Starter

- The starting current is high (5-8 times the full load current), so a higher rating of switch gears is required to be installed.

- Direct online Starter causes a significant dip in voltage, hence suitable only for small motors. However, it can be used to start a large-rated motor up to 90 KW if the power transformer capacity permits.

- DOL Starter reduces the lifespan of the machine because of higher thermal and mechanical stresses on the system.

Applications of direct online Starter

DOL starters are used to start small-rating motors like water pumps, compressors, conveyors, etc. The compressor motor starts at no load; therefore, this starter is suitable for compressor motors. The Squirrel cage induction motor coupled through fluid coupling can also be started with a DOL starter.

Good