Introduction to Star Delta starter:

Star delta starters are widely used to start a three-phase induction motor. In star-delta starting, the motor is first connected in star connections, and after achieving the required speed, it is connected in delta connections.

The small rating induction motor can be started on a direct online starter (DOL). The large rating motor, if started on DOL, draws a large starting current. The large starting current may cause a voltage dip in the system voltage, which may further cause power disturbance in the electrical network. To limit the starting current, Star Delta Starter is used.

Why is the starter needed for the induction motor?

When the induction motor is started, it draws a large starting current because the rotor impedance is more inductive at the start of the motor. The motor’s slip is unity when it is started.

The voltage induced in the Rotor is;

Er = s*Es* stator rotor turns ratio

Where,

Er = Rotor induced voltage

s = Slip

At starting, slip=1

Rotor Current(Ir) = Er/Zr

Where,

Er and Zr are the rotor voltage and impedance, respectively.

The rotor impedance Z2=√(Rr2 + s*Xr2)

The rotor reactance(Xr) is more than the rotor resistance.

Xr= 2πsfs XL

At the start, the slip of the motor is unity, and the frequency of the rotor-induced voltage is equal to the stator supply frequency. Therefore, the rotor’s reactance is higher at the start of the motor. Thus, at starting, the rotor draws a large inductive current.

Moreover, the power factor of the motor is very low during starting. As a result, the starting torque delivery of the motor is very poor. As the motor accelerates towards its base speed, the slips and the rotor voltage get reduced, and the current decreases accordingly.

How to Reduce the Starting Current of the Motor?

We use a star delta starter to limit the starting current of the induction motor.

Methods of reducing starting current are-

- Reducing the stator voltage- Star-delta starter

- Adding external resistance to the rotor circuit- For slip ring motor only

We will now discuss how the starting current can be limited with the use of a star delta starter.

What is the Star Delta Starter?

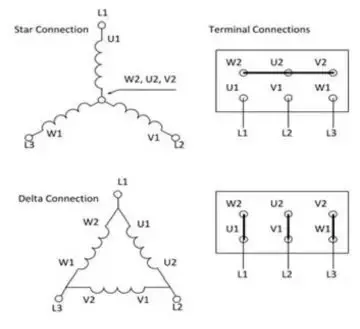

The winding of the stator of the motor is brought into the stator terminal box of the motor. The winding can be connected in the star or delta configuration.

When the motor is started by the DOL starter, the winding is configured in the Delta. The six pairs of winding are brought in the starter panel to connect the winding in star configuration initially for a certain time, and after, the motor is connected in the delta configuration with star/delta contactor logic.

Principle of Working of Star Delta starter

The motor is first started by connecting its stator winding in a star configuration. The phase voltage in the star configuration is 1/√3 of the phase-to-phase or line voltage. Thus, the voltage applied to the stator winding is about 58 % of the line voltage. The starting stator current reduces to 1/√3 of the full load current when the motor is started in a star winding configuration.

However, reducing the starting current also adversely affects the motor’s starting torque-delivering capacity. The torque of the induction motor is proportional to the square of the applied voltage.

T= Slip* V2 ———-(1)

At starting, slip=1

Tst= K* V2 —————(2)

Tst= K* (1/√3)2

Tst= K*1/3 —————(3)

The torque-delivering capacity of the motor becomes 33 % of the full torque capacity of the motor during the running of the motor in a star configuration. Therefore, the Star Delta starter can be used for starting loads that require less starting torque.

Circuit Diagram of Star Delta Starter

Star- Delta Starter Circuit Description:

When the Start push button is pressed, the K1T timer gets energized, and it operates the star contactor KM1 and then the main contactor KM3. The motor starts in the star configuration and operates in the star for the time the timer K1T is programmed.

After the lapse of the timing of the K1T timer, the delta contactor KM2 operates, and the motor now runs in delta mode. The overload relay can be mounted in the mainline or in the delta circuit. In the diagram, the overload relay is mounted in the delta circuit. In the delta circuit, the relay setting must be 1/√3 of the motor’s full load current.

Applications of the star delta starter :

The star delta starter reduces the starting current. However, the starting torque is also reduced. With the star delta starter, the starting torque is reduced by up to 66 %. The motor can deliver only 33 % torque in star mode. The starter is best suited for applications where the mechanical load demands less starting torque.

WHAT IS THE DIFFERENCE BETWEEN IMPEDANCE VOLTAGE REDUCED STARTER AND SOFT STARTER ON PUMPS