In high-performance power electronics, milliseconds can be the difference between safe operation and catastrophic failure. A semiconductor fuse is specifically designed to protect sensitive devices like SCRs, IGBTs, and diodes, which are especially vulnerable and can exceed their thermal limits in microseconds under fault conditions.

Standard protection devices often react too slowly to prevent damage, which is why specialized ultra-fast semiconductor fuses exist. These fuses quickly interrupt faults before the peak current occurs, sharply limiting energy let-through and protecting sensitive components.

This article examines their operating behavior, performance characteristics, and the critical role they play in protecting modern electronic systems—while also comparing them to standard HRC fuses to clarify where each type fits best.

What is a Semiconductor Fuse?

A semiconductor fuse is a type of high rupturing capacity (HRC) fuse designed for ultra-fast short-circuit protection of sensitive semiconductor devices. It can interrupt fault currents in microseconds, preventing damage to components such as Silicon Controlled Rectifiers (SCRs), Insulated Gate Bipolar Transistors (IGBTs), diodes, triacs, thyristors, and other solid-state power devices.

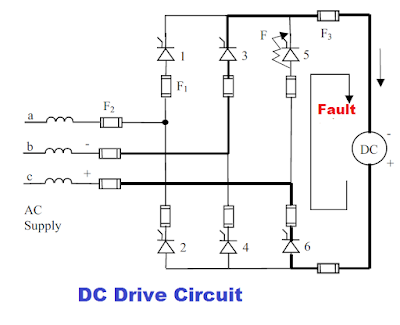

These fuses are essential in power electronics applications, including rectifier converters, inverters, Uninterruptible Power Supplies (UPS), DC drives, Variable Frequency Drives (VFDs), slip power recovery systems (SPRS), and other high-performance electronic equipment.

For reliable protection, the thermal energy (I²t) rating of a semiconductor fuse is always selected to be lower than the I²t rating of the semiconductor device. This ensures the fuse melts before the device is exposed to damaging energy levels.

Despite the name, a semiconductor fuse does not contain semiconductor material. It is a specially engineered HRC fuse optimized to safeguard semiconductor devices by combining ultra-fast operation with precise energy limitation.

Why Fast-Acting Semiconductor Fuses are Essential for Device Protection

Semiconductor devices are extremely sensitive to overcurrent and short-circuit faults. During a short circuit, the fault current passing through the device rapidly raises its junction temperature. If this temperature exceeds the device’s rated capacity, permanent failure can occur in a fraction of a second.

Even moderate overcurrents can be harmful. When the current exceeds the rated value, device temperature rises quickly. If the short-circuit current is not immediately interrupted, the semiconductor device may be destroyed before any other protective device can react.

A critical factor is that the resistance of semiconductor devices halves for every 10 °C rise in temperature. This positive feedback accelerates heating, making fast-acting protection essential. Overloading or fault conditions can therefore cause irreversible thermal damage unless addressed instantly.

To prevent such failures, fast-acting semiconductor fuses—with extremely low pre-arcing time and precisely matched I²t ratings—are installed to disconnect the fault before the device reaches its thermal limit.

These fuses are widely used in power electronics applications such as thyristor-based DC drives, Variable Frequency Drives (VFDs), Uninterruptible Power Supplies (UPS), and rectifier systems, where protection speed is critical.

Construction of a Semiconductor Fuse

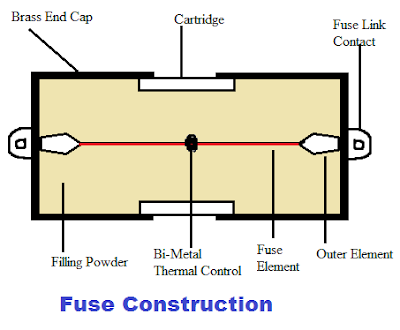

A semiconductor fuse is a specialized type of High Rupturing Capacity (HRC) fuse designed for ultra-fast fault protection. It consists of three main components:

- Fuse Element – A precision-engineered conductive strip that carries the current during normal operation.

- Filler Material – Typically fine silica sand or quartz, which surrounds the fuse element to aid heat dissipation and absorb arc energy during fault conditions.

- Fuse Body – A robust enclosure, often ceramic, that provides mechanical strength and insulation.

When current flows through the fuse element, heat is generated according to its resistance. This heat is transferred to the filler material, which dissipates it efficiently. Because of this excellent heat transfer, the fuse element can have a smaller cross-sectional area, enabling it to melt very quickly under short-circuit conditions.

During a fault, the filler not only speeds up the melting process but also absorbs the arc energy, ensuring that the fault is cleared safely without damaging surrounding equipment.

Working Principle of Semiconductor Fuse

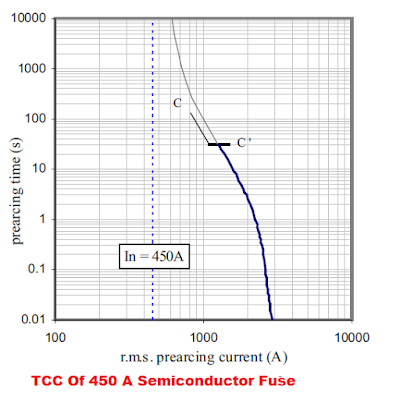

A semiconductor fuse operates on the inverse time–current characteristic principle — meaning that the higher the overcurrent, the shorter the fault-clearing time.

These fuses are specially designed to provide super-fast fault interruption, ensuring that sensitive semiconductor devices such as SCRs, IGBTs, and diodes are protected before their thermal limits are exceeded.

Key aspects of the working principle include:

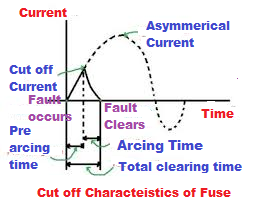

- Inverse Time–Current Response – With rising fault current, the pre-arcing time (time before the fuse starts melting) becomes extremely short.

- Thermal Matching – The fuse’s characteristics are precisely aligned with the thermal load-carrying capacity of the semiconductor device, preventing overheating.

- Current Limiting Action – By interrupting the circuit before the fault current reaches its peak, the fuse reduces thermal and mechanical stress on the protected components.

This rapid cut-off capability makes semiconductor fuses ideal for high-speed protection in applications like VFDs, UPS systems, rectifiers, and DC drives.

Characteristics of Semiconductor Fuses

Semiconductor devices have low thermal reserves and can operate reliably only if their junction temperature stays below 125°C. Since the temperature margin between normal operation and failure is very small, super-fast-acting fuses are essential for their protection.

Key characteristics include:

- Low Thermal Reserve – The fuse uses small limiter cross-sections, allowing it to reach melting temperature quickly under overcurrent conditions.

- High-Speed Response – Designed to react within microseconds to prevent excessive heat buildup in sensitive semiconductor devices.

- High-Quality Materials –

- Fuse Element: Made of oxidant-resistant fine silver, chosen for its conductivity and durability.

- Notches: Reduced cross-section areas on the fuse element ensure precise and rapid melting.

- Melting Point: Silver element melts at 960°C, allowing it to withstand high operating temperatures before failure.

- Durable Body – Constructed from thermally stable aluminum oxide ceramic for mechanical strength and heat resistance.

These design features enable semiconductor fuses to limit fault energy effectively and protect devices in critical applications such as VFDs, inverters, UPS systems, and DC drives.

Cut-Off Characteristics of Semiconductor Fuses

The cut off characteristics of fuse describe how quickly a fuse interrupts fault current before it reaches its peak value. In the case of semiconductor fuses, these characteristics are critical because power semiconductor devices (such as SCRs, IGBTs, and diodes) can tolerate only very short fault durations before being damaged.

A semiconductor fuse is also known as a current-limiting fuse or high breaking capacity (HRC) fuse. In some contexts, it is referred to as a rectifier fuse or ultra-fast fuse due to its extremely short response time.

One of the key performance indicators is the pre-arcing time—the time taken by the fuse element to melt and initiate fault interruption. For semiconductor fuses, this time is extremely short to prevent excessive energy let-through.

Semiconductor Fuse vs HRC Fuse – Key Differences

| Parameter | Semiconductor Fuse | HRC Fuse |

| Purpose | Designed to protect sensitive semiconductor devices like SCRs, IGBTs, and diodes. | General-purpose fuse for electrical circuits and equipment protection. |

| Speed of Operation | Ultra-fast acting, interrupts fault current within microseconds. | Fast acting but slower than semiconductor fuses. |

| I²t Value | Very low I²t matching the thermal capacity of semiconductor devices. | Higher I²t compared to semiconductor fuses. |

| Construction | Fine silver element with reduced cross-section notches; ceramic body with quartz/sand filler. | Copper or silver element; ceramic body with filler material. |

| Thermal Capacity | Low thermal reserve to melt quickly and limit energy let-through. | Higher thermal reserve for general protection. |

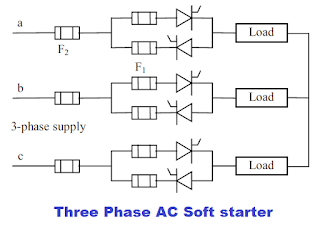

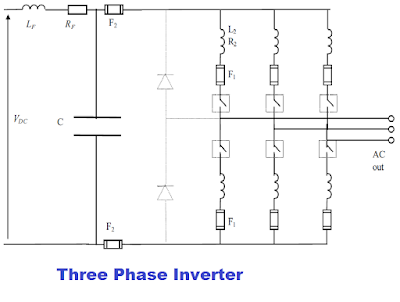

| Applications | Power electronics, UPS, VFDs, DC/AC drives, inverters, soft starters. | Switchgear, distribution panels, motor circuits, transformers. |

| Cost | Higher due to precision design and materials. | Lower compared to semiconductor fuses. |

Applications of Semiconductor Fuses

Semiconductor fuses are widely used for the protection of power semiconductor devices. The semiconductor fuses are used in:

- DC Drives

- AC Drives

- UPS system

- Soft starter

- Electronic equipment

These fuses are also used in soft starters.

The semiconductor fuses are used for the inverter with IGBTs, thyristors, or Power transistors.

Conclusion

Semiconductor fuses bridge the gap between raw electrical fault conditions and the survival of precision power electronics. Their unmatched fault-clearing speed, low I²t values, and current-limiting action make them indispensable wherever semiconductor devices operate under demanding loads.

Selecting the right fuse is not just about ratings—it’s about matching the fuse’s thermal and electrical profile to the device it protects. This ensures that even in worst-case scenarios, the device remains intact, downtime is minimized, and system reliability is preserved.

As power electronics continue to advance, the role of semiconductor fuses will only grow more important, serving as the first—and often last—line of defense against destructive overcurrent events.

Related Articles:

Thanks for such a insightful information about semiconductor fuse, It means a lot.