- Transformer Oil Defined: Transformer oil (insulating oil) is essential for cooling, insulation, and protecting transformers from oxidation.

- Types of Transformer Oil: Two main types—paraffin-based and naphtha-based—vary in oxidation rate, sludge behavior, and cooling efficiency.

- Electrical Properties: Dielectric strength is a key performance metric, with 30 kV typically the minimum acceptable value.

- Testing Importance: Regular testing helps detect deterioration, improve safety, and extend transformer lifespan.

- Properties to Monitor: Focus on dielectric strength, specific resistance, and water content to ensure reliable operation.

This article describes transformer oil testing, oil types, and their properties. Transformer Insulating Oil is used in the transformer for insulation and cooling purposes.

Whether you’re dealing with naphtha-based or paraffin-based transformer oil, understanding their electrical, chemical, and physical properties—from BDV (breakdown voltage) to water content, acidity, viscosity, and interfacial tension—is key to avoiding costly failures.

We’ll also cover ASTM and IEC testing standards, how to detect oil contamination early, and why regular transformer oil analysis can dramatically extend your equipment’s operational life.

What is Transformer Oil?

The transformer oil is obtained by fractional distillation and subsequent treatment of crude petroleum, and the transformer oil is also known as Mineral Insulating oil.

The heat generated in the transformer gets transferred to oil, and the heat gained by the transformer oil gets transferred to the transformer radiators through convection.

Finally, the heat is released from the transformer radiator to the air through radiation. Mineral oil is a good conductor of heat and a bad conductor of electricity. This virtue of mineral-insulated oil makes it most suitable for oil-filled transformers.

The transformer insulating oil also protects the winding and core of the transformer. It acts as an insulation between the core and winding and thus stops any oxidation reaction by avoiding direct contact of the oxygen with the core and winding.

Types of Transformer Oil

There are two types of transformer Mineral oil.

- Naphtha-based Transformer Insulation Oil

- Paraffin-based Transformer Insulation Oil

Naptha Oil

Naptha oil gets more easily oxidized than paraffin oil. When the oil gets oxidized, a product is formed called sludge.

The sludge formed in the Naptha oil is more soluble than paraffin oil, and it does not settle down in the bottom of the transformer tank. The sludge formed does not obstruct the convection circulation of the oil, and thus, the cooling of the transformer does not get affected.

Paraffin Oil

The oxidation rate of the paraffin oil is lower than the Neptha oil. Still, the sludge is insoluble, and the sludge gets precipitated at the bottom of the transformer tank and affects the cooling of the transformer.

The paraffin oil has more wax content in it. Paraffin-based oil is cheaper than Neptha oil.

Transformer Oil Properties and Key Parameters

Certain parameters of transformer oil are crucial for ensuring a transformer’s long service life. These parameters can be classified into:

| Transformer Oil Characteristics | Parameters |

| Electrical Parameters | Dielectric strength, dielectric dissipation factor, and specific resistance |

| Chemical Parameters | Water content, Acidity, and Sludge content |

| Physical Parameters | Inter facial Tension, Viscosity, Flash point and Pour point |

Electrical Properties of Transformer Oil

Dielectric Strength of Transformer Oil

The dielectric strength of oil is also known as breakdown voltage(BDV). The breakdown voltage of transformer oil is the maximum voltage for which the transformer oil remains in an insulating state.

If the voltage exceeds the BDV of the transformer oil, the current starts flowing through the oil, and the transformer oil loses its insulating property.

The breakdown voltage of the transformer oil is tested using a transformer oil BDV test kit. The transformer oil BDV test kit has two electrodes separated by a 2.5 mm distance. A transformer oil BDV test kit with 4 mm electrode separation is also used.

The breakdown voltage is measured by observing the voltage at which the sparking is observed between the electrodes.

The voltage is increased at a rate of 2 KV/sec. The voltage is noted when the spark is observed. The same sample is tested six times, and the breakdown voltage is measured. The average of all six readings of breakdown voltage is the final breakdown voltage of the transformer oil.

The lower BDV of oil indicates moisture and other conducting substances in the oil. The clean oil with low moisture content has higher BDV than the oil with high moisture content and other impurities.

As per IEC, the transformer oil with a minimum breakdown voltage of 30 KV can be safely used in a transformer.

The standards IEC60156/ ASTM D-877 / IS6792 can be referred to for transformer oil BDV measurement.

Read detailed article: Transformer Oil BDV Test – Procedure, Minimum Values & Standards

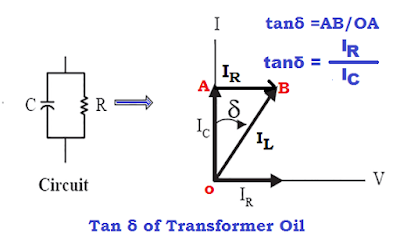

Dielectric Dissipation Factor-Tan Delta of Transformer Oil

The dielectric dissipation factor of the transformer oil is tangent of the delta angle, which shows the dielectric loss of oil.

Dielectric dissipation factor is also known as tan delta(tan δ) transformer oil.

The dielectric dissipation or loss factor is measured according to IEC 60247/ ASTM D1169/ IS 6262 standards. A high tangent delta of the transformer oil indicates the deterioration of the oil.

If the tan delta of the transformer is more than 0.05% at 25 °C, the transformer should be analyzed in a laboratory to determine the cause of the high dissipation factor.

When the insulating material is placed between the live and earth parts, the leakage current will flow. The transformer oil is an insulating or dielectric material, and the magnitude of the leakage current indicates the quality of the insulation.

The leakage current flowing through the oil indicates the quality of the transformer oil.

In an ideal insulating or dielectric material, the leakage current flowing through it must lead the voltage by 90 degrees.

However, in reality, the current flowing through the insulating material does not lead the voltage by 90° but leads by something less than 90°. The extent to which the phase shift is less than 90° indicates the deterioration of the insulation quality.

The perfect insulator must draw a capacitive current, and the resistive current must be zero. The more the resistive current, the more the dielectric dissipation factor or tan delta or loss angle.

The loss angle or tan delta must be as low as possible for better insulation. If the loss angle is small the resistive component of the current is small, which indicates a high resistive property of the insulating material.

The high resistive insulation is a good insulator. The high value of the tan delta indicates that there are impurities in the transformer oil.

The resistivity and the tan delta have an inverse relationship. The transformer oil with a lower loss angle or tan delta has higher resistivity.

Specific Resistance of Transformer Oil

The specific resistance is proportional to its resistivity and length and inversely proportional to the cross-sectional area. It also depends on the temperature of the transformer oil.

The specific resistance of the transformer oil is a measurement of DC resistance between two opposite sides on one cm3 block of oil. The unit is Ohm-cm at a specific temperature. The resistivity of the oil reduces drastically with an increase in temperature.

If the transformer is shut off for a long time, the temperature of the transformer oil is the same as that of the ambient, and the resistivity of the transformer oil increases. With a full load, the temperature of the transformer oil may reach up to 90 °C, especially in overloaded conditions.

Thus, the transformer oil resistance should accommodate the two values of the specific resistance at 27 °C and 90 °C.

The specific resistance of the transformer oil can be measured using the standard IEC 60247/ ASTM D-1169/ IS 6103.

As per IEC 60247, the electrification time and field strength proposed are 60 seconds and 250V/mm, respectively. The voltage and current ratio are measured to calculate the specific resistance of the transformer oil.

As per ASTM D-1169, the electrification time and the field strength proposed are 60 seconds and 200 V/mm, respectively. In this process, the specific resistance of the oil is measured by applying both polarity voltage and the average of both readings, which is the specific resistance of the transformer oil.

The minimum specific resistance of the transformer oil at 90 and 27 °C is 35 x1012 and 1500 x1012, respectively.

Chemical Properties of Transformer Oil

Water Content in Transformer Oil

The water content in transformer oil is a very undesirable pollutant. The dielectric strength of the transformer oil lowers with an increase in the moisture content in the transformer oil.

The breather of the transformer is filled with moisture-absorbent material, silicon gel so that water does not come in contact with the transformer oil.

The paper of the transformer is highly hygroscopic. The paper absorbs the moisture of the oil, and thus, the paper insulation property deteriorates.

With an increase in temperature, the absorbed moisture in the paper is released, and it gets mixed with the transformer oil.

The transformer’s life reduces with increased moisture content in the transformer oil. The water content is measured in ppm(parts per million units).

As per IS-335, the water content in an oil is allowed up to 50 ppm.

Acidity of Transformer Oil

When the transformer oil comes in contact with the air, the oil gets oxidized. The oxidization process further accelerates with the increased temperature of the transformer.

The resistivity of the transformer oil decreases with increased oxidization. The acidity of oil deteriorates the insulation property of the paper. With the increased acidity of the transformer oil, the water becomes more soluble.

The acidity test of the transformer oil is carried out periodically to check its acidity. The acidity of the transformer oil is expressed in mg of KOH required to neutralize 1 gram of transformer oil.

Read detailed artcile on: Acidity Test of Transformer Insulating Oil

Physical Properties of Transformer Oil

Flash Point of Transformer Oil

The flash point of transformer oil is the minimum temperature at which it gives off vapor. If the ignition source comes in contact with the vapor-air mixture, it catches fire. The flash point of transformer oil is 140.

No burning occurs below the flash point. A high flash point of transformer oil is desirable. This property of the transformer oil is very important, especially considering the fire hazards associated with it.

Read detialed article on: Flash Point of Transformer Oil and its Importance

Pour Point of Transformer Oil

The pour point is the minimum temperature at which transformer oil starts flowing. Paraffin oil has a higher pour point than naphtha oil because paraffin oil has more wax content than naphtha oil. Paraffin oil is suitable for warm climate conditions.

Viscosity of Transformer Oil

The resistance to flow is known as the viscosity of the liquid. The resistance to flow obstructs the convection circulation of oil inside the transformer. The viscosity lowers with an increase in the temperature; it flows faster or more efficiently.

Good transformer oil should have a low viscosity so that it offers less resistance to flow and does not affect the cooling of the transformer.

Inter Facial Tension(IFT) of Transformer Oil

The interfacial tension describes the tension between two liquids. In the case of the transformer, oil, and water—the attractive molecular force between water and oil measures interfacial tension.

The impurity in the oil or contamination of the transformer oil lowers the IFT. The unit of IFT is dyne/cm or milli-Newton/meter.

Transformer Oil Testing

The transformer oil must be periodically tested to ensure the trouble-free operation of the transformer. The transformer oil is a critical key factor for the reliable operation of the transformer. International standards set various testing standards and procedures, most of which are set by ASTM.

Transformer oil testing is a diagnostic process that helps in identifying the health of both the oil and the transformer. By checking parameters like dielectric strength, acidity, moisture content, and gas levels, engineers can prevent sudden breakdowns, improve safety, and extend transformer life.

Parameters Checked in Transformer Oil Testing

The following transformer oil parameters are tested using the ASTM( American Society for Testing and Materials) standard.

| Test Name | Purpose | ASTM Standard |

| Standard Specifications for Mineral Insulated Oil | Ensures oil meets general mineral oil quality requirements | ASTM D3487 |

| Dielectric Breakdown Voltage Test | Measures insulation strength | ASTM D877 |

| Interfacial Tension (IFT) Test | Detects oil contamination | ASTM D971 |

| Acid Number Test | Checks acidity and oil degradation | ASTM D664 |

| Specific Resistance Test | Evaluates insulation property | ASTM D1169 |

| Liquid Power Factor Test | Measures dielectric losses | ASTM D924-08 |

| Corrosive Sulphur Test | Detects sulfur that causes corrosion | ASTM D1275 |

| Visual Examination | Identifies sludge, turbidity, and color change | ASTM D1524 |

Each of these parameters gives insight into the transformer oil condition. For example, dielectric breakdown voltage test checks the oil’s insulating strength, while interfacial tension helps detect contamination. Acid number test identifies oil degradation, and visual examination detects sludge and discoloration.

Dissolved Gas Analysis (DGA) in Transformer Oil Testing

Apart from the above tests, the Dissolved Gas Analysis(DGA) Test is also conducted to determine the health of the transformer oil. The DGA test is helpful for predictive maintenance of the transformer.

The DGA test is one of the most critical transformer oil testing methods because it detects gases like hydrogen, methane, ethylene, and acetylene, which indicate different types of faults such as arcing, overheating, or partial discharge. This makes it a powerful tool for condition monitoring and predictive maintenance.

Read Detailoed artcile on: Dissolved Gas Analysis (DGA) Test of Transformer Oil

Common Problems in Transformer Oil Testing

During transformer oil testing, certain faults and anomalies in the transformer can be detected by analyzing the gases dissolved in the oil. The table below highlights the most common issues and their key indicators:

| Fault | Key Gas | Explanation |

| Corona Discharge | Hydrogen | Low-energy discharges produce hydrogen and small amounts of methane, ethylene, and ethane. |

| Arcing | Acetylene | High-energy discharges generate large amounts of hydrogen or acetylene, with minor quantities of methane and ethylene. |

| Overheated Cellulose | Carbon Monoxide | Excessive heating of cellulose insulation releases carbon monoxide into the oil. |

| Overheated Oil | Methane and Ethylene | Overheating oil produces methane and ethylene (~300°F) or methane and hydrogen at higher temperatures (1,112°F). Severe faults may produce traces of acetylene. |

Why Transformer Oil Testing is Important

Transformer oil testing is an essential part of preventive maintenance that ensures the reliable operation of transformers. Proper testing allows you to monitor the condition of the oil and detect early signs of deterioration or contamination. Key benefits of transformer oil testing include:

- Determine essential electrical properties: Transformer oil testing measures critical properties such as dielectric strength, acidity, moisture content, interfacial tension, and power factor. These properties indicate whether the oil can continue to provide effective insulation and cooling.

- Assess oil suitability for continued use: Not all transformer oils degrade at the same rate. Testing helps identify whether the current oil is still suitable for ongoing operation or if it requires treatment or replacement.

- Identify need for regeneration or filtration: Over time, transformer oil can accumulate impurities, sludge, or moisture. Transformer oil testing highlights when regeneration or filtration is needed to restore oil quality and maintain transformer efficiency.

- Reduce replacement costs and extend component life: By maintaining the oil in optimal condition, transformer components experience less stress, which prolongs their operational life and reduces the need for costly replacements.

- Prevent untimely failures and ensure safety: Detecting problems early through transformer oil testing minimizes the risk of sudden failures, transformer downtime, and potential safety hazards.

- Long-term cost savings: With proper transformer oil testing and maintenance, transformer oils can last up to 30 years. Early detection of issues and timely corrective action can save thousands of dollars in repairs, replacements, and operational losses over the lifetime of the equipment.

In summary, transformer oil testing is not just a routine procedure—it is a critical investment in the reliability, efficiency, and safety of your transformers.

Frequency of Transformer Oil Testing

Typically, transformer oil testing is recommended once every year for power transformers. For highly critical transformers in substations or industries, testing may be performed every 6 months. Smaller distribution transformers can be tested every 2–3 years depending on operating conditions.

Related Articles:

2 thoughts on “Transformer Oil: Testing, Types & Properties”